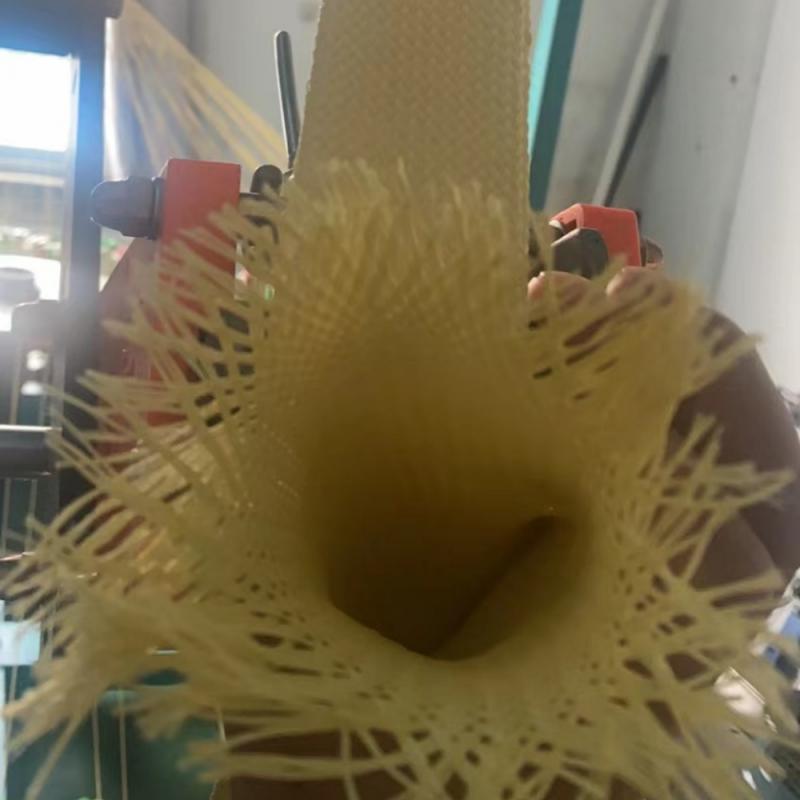

Kevlar Braided Sleeve is a premium protection solution engineered from 100% Kevlar® aramid fiber, a material renowned for its exceptional tensile strength and thermal stability. Kevlar® fiber is 20 times stronger than steel of the same diameter, making this sleeve ideal for applications where strength and durability are critical. Designed to shield cables, hoses, and wiring in harsh environments, the Kevlar® Braided Sleeve offers unmatched abrasion resistance and cut resistance, making it a go-to choice in aerospace, automotive, and other high-tech industries.

Outstanding Material Properties Kevlar® fiber provides a unique blend of thermal and mechanical properties that allow the braided sleeve to withstand extreme conditions. The material offers excellent heat resistance, with a working temperature range from -170℃ to +250℃. Unlike many other materials, Kevlar® has no melting point, ensuring that the sleeve retains its structure even under the highest heat levels. Its good chemical resistance adds to its durability, allowing it to be used in environments where exposure to chemicals or corrosive substances is common.

Cut and Abrasion Resistance One of the standout features of the Kevlar® Braided Sleeve is its superior cut resistance, making it 20 times stronger than steel wire of equivalent thickness. This makes it an excellent choice for environments where cables and hoses may come into contact with sharp edges or abrasive surfaces. The tightly braided structure provides outstanding abrasion protection, significantly extending the life of the components it covers.

Easy to Install and Maintain The Kevlar® Braided Sleeve combines strength with a flexible, cloth-like texture, making it both easy to handle and install. Its pliability allows it to move freely, which is crucial for systems requiring flexibility and movement. It can be easily cut to size using Kevlar® scissors, further simplifying the installation process. Despite its high strength, the sleeve maintains a soft and manageable texture, allowing it to fit snugly around a wide variety of cables, hoses, and wires without restricting their movement.

Wide Range of Applications Kevlar® Braided Sleeving is commonly used in aerospace, automotive, and industrial applications, where protection from abrasion, heat, and sharp objects is vital. Its robust design makes it perfect for high-performance equipment, ensuring the safety and longevity of the components it protects. From aerospace wiring harnesses to hydraulic hose covers in industrial machinery, this sleeve offers reliability in the most demanding environments.

IPv6 network supported

IPv6 network supported